100% Product Qualification Rate at Factory Shipment!

100% Customer Complaint Resolution Rate!

100% Metal Components Utilize 304/316 Stainless Steel (Unless Specified Otherwise)!

Ergonomic Details for an Exceptional User Experience!

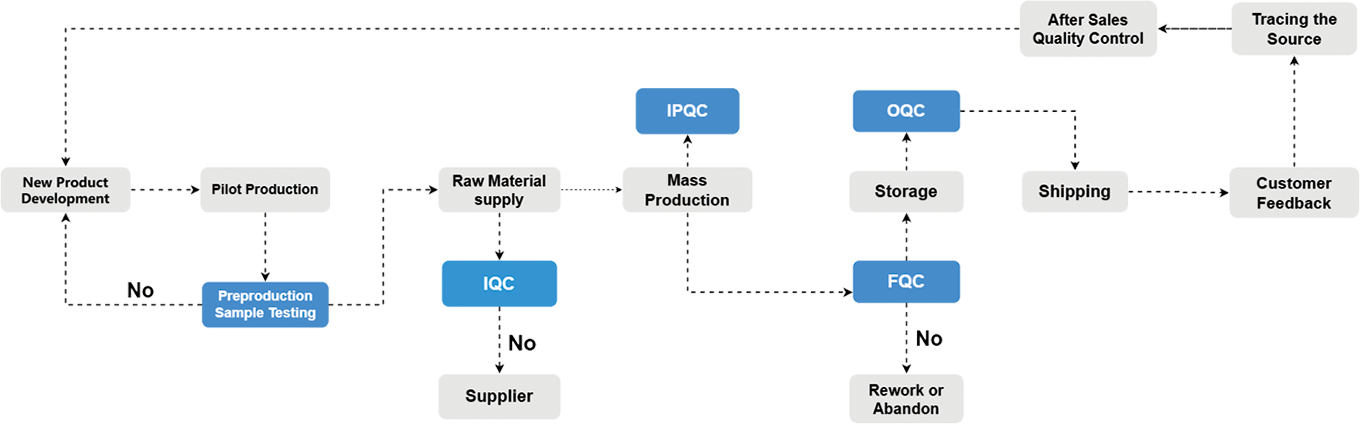

"Quality is the result of the production process, not just the outcome of inspections." is the core philosophy of Bestware's quality management. Quality management is deeply ingrained in every detail of our research and development, as well as production processes, rather than merely relying on final inspection stages. We are committed to ensuring excellence at every step, utilizing ATEQ high-precision leak detectors to achieve 100% leak-free products, accompanied by a comprehensive quality control system that spans from new product development to bulk production, ensuring that every product is a masterpiece.

At the nascent stage of product development, we are committed to fundamentally ensuring the practical effectiveness and solid reliability of our products through meticulous design and deep insights into customer needs. Before mass production, we rigorously test every sample to identify and eliminate flaws in the design phase, ensuring products exceed customer expectations and set a strong foundation for successful production.

Thoroughly examines and analyzes the monitoring data collected during the production process, aiming to precisely enhance product quality, effectively increase production yield, and significantly reduce delays, thereby ensuring efficient and smooth production.

Good products need solid after-sales management. We've built an efficient control system for continuous improvement and customer satisfaction.

At the nascent stage of product development, we are committed to fundamentally ensuring the practical effectiveness and solid reliability of our products through meticulous design and deep insights into customer needs. Before mass production, we rigorously test every sample to identify and eliminate flaws in the design phase, ensuring products exceed customer expectations and set a strong foundation for successful production.

Functional Test

Assembly Test

Usage Test

Strength Test

High Temperature Test

High Pressure Test

Life Cycle Test

Load Test(hose)

Tensile Test

Appearance Test

Salt Spray Test

Acid Resistance Test

Adhesion Test

Mold Test

Dimensional Inspection

Functional Inspection

Safety Test

Heat Resistance Test

Electrical Safety Test

Anti-Backflow Test

Filtration Function Test

Raw Material Control

Composition Analysis

Color Code Inspection

Dimensional Inspection

Component Inspection

Dimensional Inspection

Visual Inspection

Functional Inspection

Material Property Test

Final Assembly

Manufacturing Special Jigs and Fixtures

Establishing SOP

(Standard Operating Procedure)

Overall Test

Functional Test

Leak Test

"Product quality is achieved through the manufacturing process, not inspected into existence."